3D printing

Biomanufacuring

3D printing of materials has been widely explored for the rapid fabrication of complex soft structures and devices. When combined with material design, 3D printing has been demonstrated to open a variety of possibilities for biological applications, including biomaterial design, biomedical support structures and implants, biorobotics, microfluidics for drug screening and delivery and organoids development. Despite intensive investment and research progress in the field, several major challenges cripple the further development and adoption of 3D biomanufacturing: limitation in material compatibility, scalability for industrial mass production, guided vascularization and compatibility with existing platforms or pipelines, and technological accessibility.

Working with biological and chemical engineers, our work in this field is best manifested by the following multidisciplinary approaches to address the above challenges.

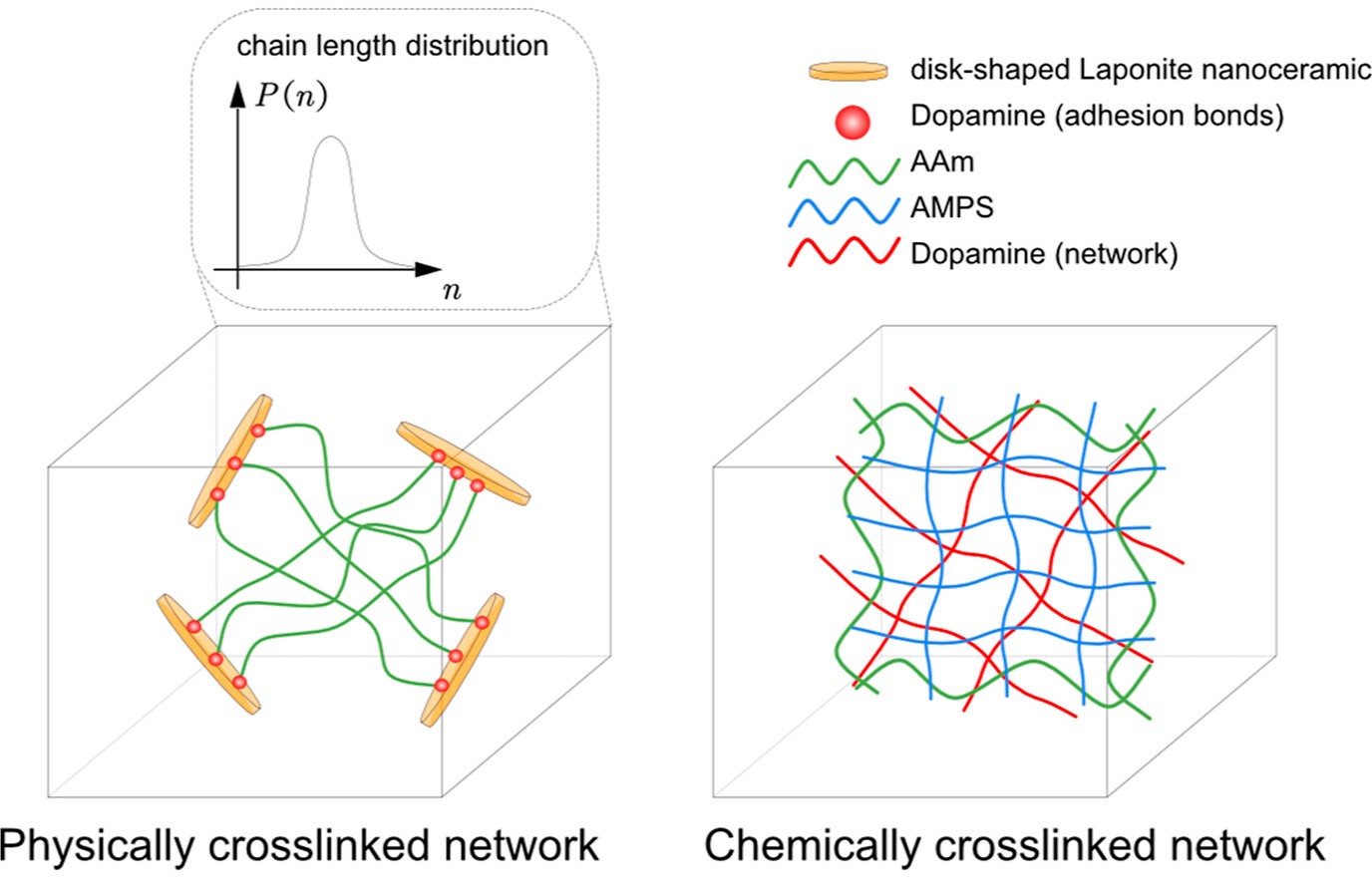

Material Design: In this work, we demonstrate a mussel-inspired (polydopamine) PDA hydrogel through the incorporation of a classical double network (2-acrylamido-2-methylpropanesulfonic acid) PAMPS/(polyacrylamide) PAAm to achieve simultaneously tailored adhesiveness, toughness, flexibility and biocompatibility and validate the 3D printability of such a hydrogel into customized architectures. The combination of desired properties is achieved through the design of a reversible cross-linking of PDA and PAMPS together with the long-chain PAAm cross-linking network. The reversible cross-linking of PDA and PAMPS is capable of dissipating mechanical energy under deformation. Meanwhile, the long-chain PAAm network contributes to maintaining a high deformation capability.

Schematics of the interpenetrating hydrogel with different component polymer networks. We establish a theoretical framework to quantify the contribution of the interpenetrating networks to the overall toughness of the hydrogel, which also provides guidance for the rational design of materials with the desired properties. At the same time, this work manifests a new paradigm of printing adhesive, tough, and biocompatible interpenetrating network hydrogels to meet the requirements of broad potential applications in biomedical engineering, soft robotics, and intelligent and superabsorbent devices. (Zhang et al., 2023)

Bioscaffold: The lack of experimental models and tools to observe and manipulate myelination in vitro has constrained progress in understanding neurological diseases, and ultimately developing effective therapies. To address this problem, we developed synthetic mimics of neuronal axons, representing key geometric, mechanical, and surface chemistry components of biological axons. Utilizing stereolithography, our 3D printing approach provides the capacity to vary independently the complex features of the artificial axons that can reflect specific states of development, disease, or injury.

Features of artificial axons can be varied to investigate the impact of individual cues, including stiffness, diameter and coating, on cell behavior. (Espinosa-Hoyos et al., 2018)

Technological Improvement: In additive manufacturing, overcoming adhesion at the cured resin interface can promote the speed and accuracy of stereolithography. Inspired by the peristome surface of the pitcher plant, we propose a slippery surface that exhibits low adhesive energy due to the separation between the cured resin and the solid interface. We demonstrate that this surface can also increase the liquid resin refilling speed, making it effective for continuous 3D printing (Wu et al., 2018). A follow-up work on this features a continuous 3D printing technology from one single droplet. By leveraging the three-phase contact line of the resin droplet, we demonstrate the capability of constructing delicate 3D structures using this method with high material utilization efficiency, thus enhancing the scalability of this approach for mass production (Zhang et al., 2020).

(Top) Continuous 3D construction on the ultra-low adhesive energy interface through simultaneously lifting the supporting. (Bottom) Formation of a stent-like hollow structure from a single droplet.

Overall, our work presents a new paradigm of designing and fabricating novel materials to meet the requirements of broad potential applications in biomedical engineering, soft robotics, and intelligent and superabsorbent devices.

References

2023

- 3D Printing of Interpenetrating Network Flexible Hydrogels with Enhancement of AdhesivenessACS Applied Materials & Interfaces, 2023

2020

- Continuous 3D printing from one single dropletNature communications, 2020

2018

- Engineered 3D-printed artificial axonsScientific reports, 2018

- Bioinspired ultra-low adhesive energy interface for continuous 3D printing: reducing curing induced adhesionResearch, 2018